+86-13961672821

+86-510-86268020

trust@hi2000.com

trust@hi2000.com

Room 807,No.169 Changjiang road,Huifu plaza,New centre,Jiangyin,Jiangsu China

| Availability: | |

|---|---|

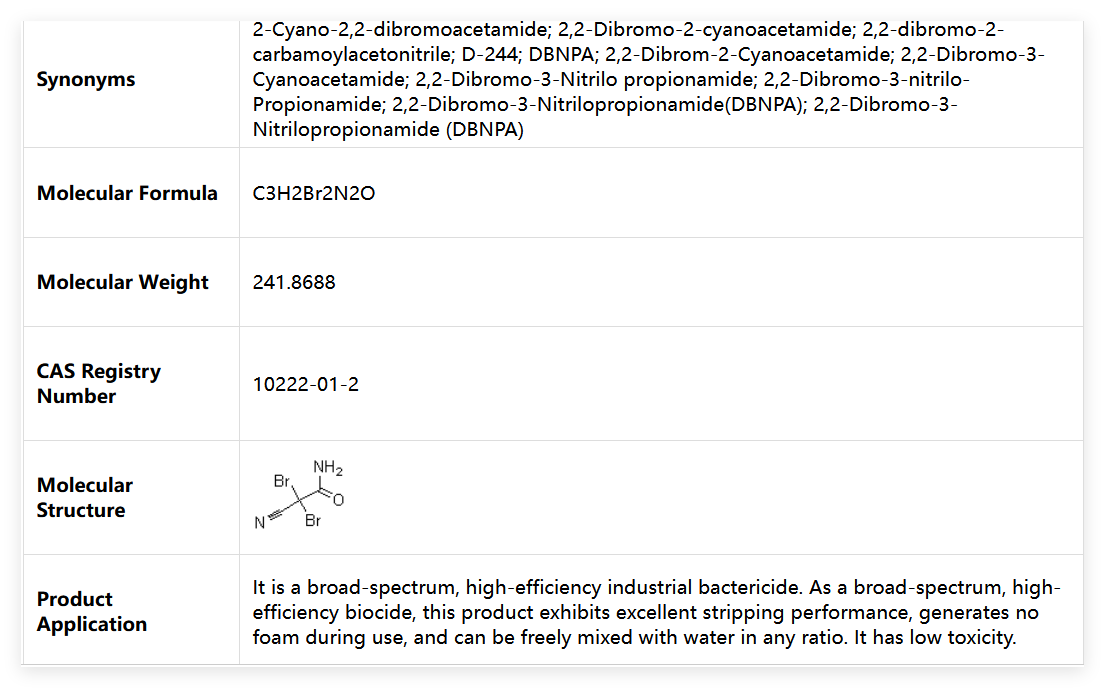

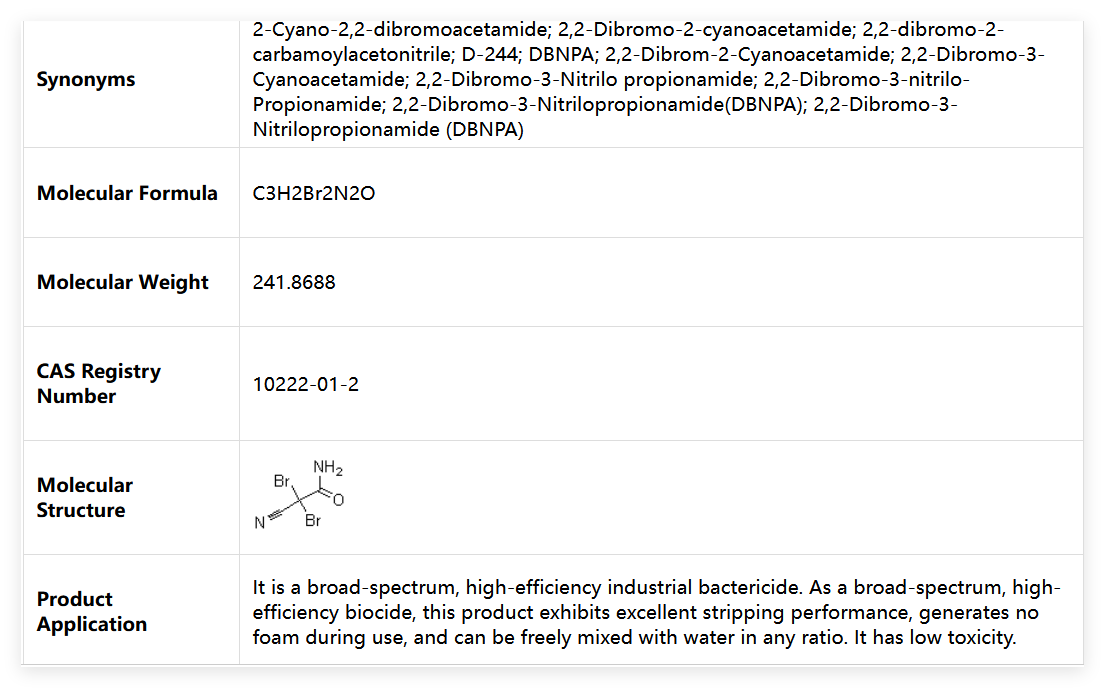

Product Name | 2,2-Dibromo-3-Nitrilopropionamide (DBNPA) |

2,2-Dibromo-3-nitrilopropionamide (abbreviated as DBNPA) is a broad-spectrum and high-efficiency biocide dedicated to microbial control in industrial systems. Its CAS number is 10222-01-2, EINECS number is 233-539-7, molecular formula is C₃H₂Br₂N₂O, and molecular weight is 241.869. Under normal conditions, the product appears as white crystals or colorless to pale yellow liquid, with a slight musty pungent odor. It not only retains the strong bactericidal properties of bromine-based compounds but also achieves adaptability to different environments through molecular structure optimization.

In terms of physicochemical properties, its density is stable at 2.5±0.1 g/cm³, melting point ranges from 122-125℃ (literature-verified value), boiling point can reach 221.5±40.0℃ (at 760 mmHg), and flash point is 87.8±27.3℃. It is not easy to volatilize or decompose under normal industrial operating temperatures. In terms of solubility, although it is only slightly soluble in water (solubility: 15 g/L), it can quickly dissolve in common industrial solvents such as methanol, acetone, and ethanol, and is slightly soluble in benzene and toluene, which can flexibly meet the addition requirements of different systems. During storage, it only needs to be sealed and placed in a cool and dry environment; decomposition can be avoided when used in accordance with specifications. In addition, the storage area must be locked to ensure operational safety.

High Efficiency with Low Dosage, Optimal Control Cost**: Only a 20% DBNPA solution with a concentration of 15 ppm is required to simultaneously achieve inhibition of microbial reproduction and removal of filler slime masses. For example, when used in industrial cooling towers, it can quickly restore the evaporative efficiency of equipment. Compared with traditional biocides, the dosage is reduced by more than 30%, lowering long-term usage costs.

Broad-Spectrum Bactericidal Activity, Suitable for Multiple Scenarios**: It has strong killing effects on various microorganisms such as bacteria, fungi, and algae. There is no need to replace agents for different microorganisms, and it can cover the needs of multiple industries including papermaking, cooling systems, and metalworking, reducing the types of agents in stock.

Clear Mechanism of Action, Low Resistance Risk**: It works through a dual mechanism of "penetrating cell membranes to disrupt redox reactions + selective bromination/oxidation of enzyme metabolites". Microorganisms are less likely to develop resistance, and stable control effects can still be maintained after long-term use, avoiding frequent adjustments to the medication plan.

Controllable Synthesis Process, Stable Quality**: It is prepared using conventional raw materials such as chloroacetic acid and malononitrile through steps including neutralization, cyanidation, esterification, ammonolysis, and bromination. Controlling the bromination process below 40℃ can effectively prevent decomposition. The purity of industrial-grade products is stably maintained at ≥98%, with small differences between batches.

As a core biocide for pulp and process water, it can effectively inhibit the reproduction of bacteria and molds in pulp, preventing paper spots and breakage caused by pulp mildew. At the same time, it can remove biological slime in papermaking equipment, avoiding pipe blockage by slime that affects production efficiency. It is suitable for various pulp types such as wood pulp and straw pulp.

Used in industrial cooling water and air conditioning circulating water systems, it can not only kill harmful microorganisms in water such as *Legionella pneumophila* and heterotrophic bacteria but also remove slime masses on cooling tower fillers to restore heat dissipation efficiency. Experimental data shows that after use, the evaporative efficiency of cooling towers can be increased by 15%-20%, reducing equipment shutdown caused by insufficient heat dissipation.

When added to metalworking lubricating oil, it can prevent the lubricating oil from deteriorating and becoming odorous due to microbial growth, extending the service life of the oil. When used in wood coatings and industrial coatings, it can inhibit mold growth during coating storage and construction, avoiding mold spots and discoloration of the coating, and ensuring the appearance and adhesion of the coating film.

As an industrial sewage treatment agent, it can assist in decomposing organic pollutants in sewage and kill pathogenic microorganisms in sewage, reducing the risk of sewage discharge. In addition, it can also be used as a pharmaceutical intermediate for the synthesis of specific antibacterial drugs, expanding the connection application between the chemical and pharmaceutical fields.

Transportation Classification: Classified as Class 6.1 Toxic Substances in accordance with the *Dangerous Goods Transportation Regulations*, with UN number 3439 and Packaging Grade III. It shall be packed in dangerous goods packaging that meets the requirements of GB 190.

Packaging Requirements: Packed in iron drums or HDPE drums lined with polyethylene, with optional specifications of 25kg/drum or 50kg/drum. The drum mouths shall be tightly sealed to prevent leakage. "Toxic Substance", "Avoid Sunlight", and "Moisture-Proof" labels shall be affixed to the outer packaging, and the UN number, product name, and manufacturer information shall be marked.

Transportation Taboos: Mixed transportation with food, medicines, oxidants, and acids is strictly prohibited. Transport vehicles shall be equipped with fire-fighting equipment and leakage emergency treatment equipment. Drivers shall hold dangerous goods transportation qualifications, and severe collisions, exposure to sunlight, and rain shall be avoided throughout the transportation process.

Unloading and Temporary Storage: During unloading, goods shall be handled with care to avoid packaging damage. The temporary storage area shall be cool, dry, and well-ventilated, and kept at a distance of ≥10 meters from fire sources and heat sources. In addition, the area shall be locked to prevent unauthorized personnel from entering.

Product Name | 2,2-Dibromo-3-Nitrilopropionamide (DBNPA) |

2,2-Dibromo-3-nitrilopropionamide (abbreviated as DBNPA) is a broad-spectrum and high-efficiency biocide dedicated to microbial control in industrial systems. Its CAS number is 10222-01-2, EINECS number is 233-539-7, molecular formula is C₃H₂Br₂N₂O, and molecular weight is 241.869. Under normal conditions, the product appears as white crystals or colorless to pale yellow liquid, with a slight musty pungent odor. It not only retains the strong bactericidal properties of bromine-based compounds but also achieves adaptability to different environments through molecular structure optimization.

In terms of physicochemical properties, its density is stable at 2.5±0.1 g/cm³, melting point ranges from 122-125℃ (literature-verified value), boiling point can reach 221.5±40.0℃ (at 760 mmHg), and flash point is 87.8±27.3℃. It is not easy to volatilize or decompose under normal industrial operating temperatures. In terms of solubility, although it is only slightly soluble in water (solubility: 15 g/L), it can quickly dissolve in common industrial solvents such as methanol, acetone, and ethanol, and is slightly soluble in benzene and toluene, which can flexibly meet the addition requirements of different systems. During storage, it only needs to be sealed and placed in a cool and dry environment; decomposition can be avoided when used in accordance with specifications. In addition, the storage area must be locked to ensure operational safety.

High Efficiency with Low Dosage, Optimal Control Cost**: Only a 20% DBNPA solution with a concentration of 15 ppm is required to simultaneously achieve inhibition of microbial reproduction and removal of filler slime masses. For example, when used in industrial cooling towers, it can quickly restore the evaporative efficiency of equipment. Compared with traditional biocides, the dosage is reduced by more than 30%, lowering long-term usage costs.

Broad-Spectrum Bactericidal Activity, Suitable for Multiple Scenarios**: It has strong killing effects on various microorganisms such as bacteria, fungi, and algae. There is no need to replace agents for different microorganisms, and it can cover the needs of multiple industries including papermaking, cooling systems, and metalworking, reducing the types of agents in stock.

Clear Mechanism of Action, Low Resistance Risk**: It works through a dual mechanism of "penetrating cell membranes to disrupt redox reactions + selective bromination/oxidation of enzyme metabolites". Microorganisms are less likely to develop resistance, and stable control effects can still be maintained after long-term use, avoiding frequent adjustments to the medication plan.

Controllable Synthesis Process, Stable Quality**: It is prepared using conventional raw materials such as chloroacetic acid and malononitrile through steps including neutralization, cyanidation, esterification, ammonolysis, and bromination. Controlling the bromination process below 40℃ can effectively prevent decomposition. The purity of industrial-grade products is stably maintained at ≥98%, with small differences between batches.

As a core biocide for pulp and process water, it can effectively inhibit the reproduction of bacteria and molds in pulp, preventing paper spots and breakage caused by pulp mildew. At the same time, it can remove biological slime in papermaking equipment, avoiding pipe blockage by slime that affects production efficiency. It is suitable for various pulp types such as wood pulp and straw pulp.

Used in industrial cooling water and air conditioning circulating water systems, it can not only kill harmful microorganisms in water such as *Legionella pneumophila* and heterotrophic bacteria but also remove slime masses on cooling tower fillers to restore heat dissipation efficiency. Experimental data shows that after use, the evaporative efficiency of cooling towers can be increased by 15%-20%, reducing equipment shutdown caused by insufficient heat dissipation.

When added to metalworking lubricating oil, it can prevent the lubricating oil from deteriorating and becoming odorous due to microbial growth, extending the service life of the oil. When used in wood coatings and industrial coatings, it can inhibit mold growth during coating storage and construction, avoiding mold spots and discoloration of the coating, and ensuring the appearance and adhesion of the coating film.

As an industrial sewage treatment agent, it can assist in decomposing organic pollutants in sewage and kill pathogenic microorganisms in sewage, reducing the risk of sewage discharge. In addition, it can also be used as a pharmaceutical intermediate for the synthesis of specific antibacterial drugs, expanding the connection application between the chemical and pharmaceutical fields.

Transportation Classification: Classified as Class 6.1 Toxic Substances in accordance with the *Dangerous Goods Transportation Regulations*, with UN number 3439 and Packaging Grade III. It shall be packed in dangerous goods packaging that meets the requirements of GB 190.

Packaging Requirements: Packed in iron drums or HDPE drums lined with polyethylene, with optional specifications of 25kg/drum or 50kg/drum. The drum mouths shall be tightly sealed to prevent leakage. "Toxic Substance", "Avoid Sunlight", and "Moisture-Proof" labels shall be affixed to the outer packaging, and the UN number, product name, and manufacturer information shall be marked.

Transportation Taboos: Mixed transportation with food, medicines, oxidants, and acids is strictly prohibited. Transport vehicles shall be equipped with fire-fighting equipment and leakage emergency treatment equipment. Drivers shall hold dangerous goods transportation qualifications, and severe collisions, exposure to sunlight, and rain shall be avoided throughout the transportation process.

Unloading and Temporary Storage: During unloading, goods shall be handled with care to avoid packaging damage. The temporary storage area shall be cool, dry, and well-ventilated, and kept at a distance of ≥10 meters from fire sources and heat sources. In addition, the area shall be locked to prevent unauthorized personnel from entering.