+86-13961672821

+86-510-86268020

trust@hi2000.com

trust@hi2000.com

Room 807,No.169 Changjiang road,Huifu plaza,New centre,Jiangyin,Jiangsu China

| Availability: | |

|---|---|

1. Excellent Physicochemical Properties: It has a density of 2.498 g/cm³ (at 25℃). In its molecular structure, the number of hydrogen bond donors and acceptors is 30 each, with a topological polar surface area (TPSA) of 30 and a surface charge of 0. It has stable chemical properties, hardly reacting with non-strong oxidizing substances, and is suitable for various production processes.

2. High Purity Controllability: Through the preparation process of "molybdenum trioxide dissolution - ammonium sulfide impurity removal - ammonia concentration adjustment - cooling crystallization", impurities in raw materials can be effectively removed. The purity of the finished product meets the requirements of high-precision fields such as petroleum catalysis and powder metallurgy. Moreover, it contains no known sensitizing components, reducing safety risks during production.

3. Wide Application Compatibility: It not only has catalytic activity (serving as the core component of petroleum cobalt-molybdenum catalysts) but also provides trace elements required by plants (as a raw material for molybdenum fertilizers). Meanwhile, it has metal corrosion inhibition and surface treatment functions, with cross-field adaptability far exceeding that of ordinary molybdate products.

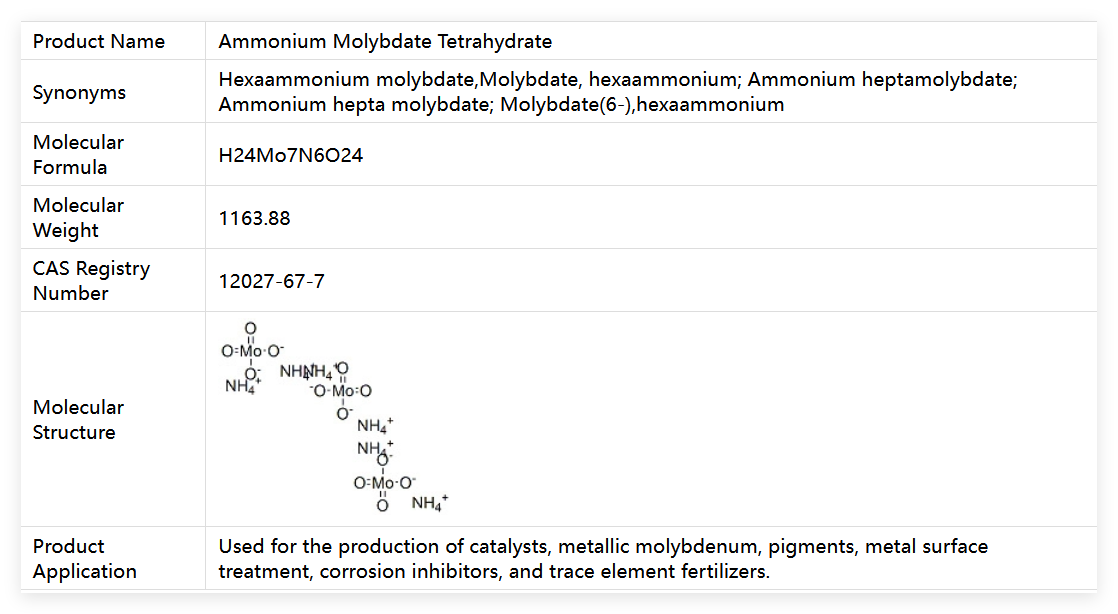

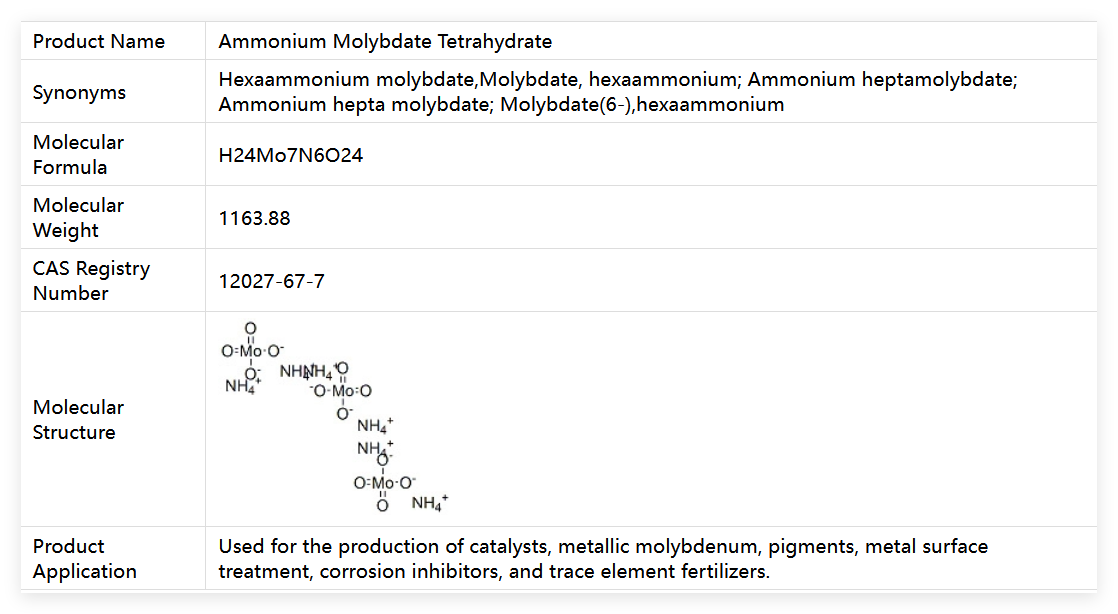

| Specification Item | Specific Parameters |

| CAS Number | 12027-67-7 |

| English Name | Hexaammonium Molybdate |

| Molecular Formula | H₂₄Mo₃N₆O₁₂ |

| Molecular Weight | 588.044 |

| Exact Mass | 593.861450 |

| Density (25℃) | 2.498 g/cm³ |

| Melting Point | 190℃ (decomposition temperature) |

| Solubility | Highly soluble in water |

| pH Value of 5% Aqueous Solution | 5.0-5.5 |

| GHS Signal Word/Symbol | Warning / GHS07 |

Hexaammonium molybdate is an inorganic compound with both stability and multi-field adaptability. As a key raw material in industrial production and agricultural applications, it appears as a colorless to pale green crystalline solid (some high-purity batches present as white crystals). It maintains stable form under normal temperature and pressure, with no obvious pungent odor.

This product is highly soluble in water, and the pH value of its 5% aqueous solution remains in the weakly acidic range of 5.0-5.5, making it compatible with most industrial reaction systems. It loses one molecule of crystal water when heated to 90℃ and decomposes when the temperature rises to 190℃. Therefore, it should be kept away from long-term exposure to high temperatures, open flames, and strong light. It can maintain good chemical stability under conventional storage conditions.

The application scenarios of hexaammonium molybdate cover two major fields: industry and agriculture, with specific application scenarios as follows:

- Petrochemical Industry: As the core raw material of petroleum cobalt-molybdenum catalysts, it is used in desulfurization, hydrogenation, and other reactions during petroleum refining. It improves the purity and quality of petroleum products and is a key auxiliary material for refining enterprises.

- Materials and Metallurgy Industry: On one hand, it can be used to prepare metallic molybdenum (a common raw material for powder metallurgy enterprises, obtaining high-purity molybdenum powder through high-temperature decomposition and reduction). On the other hand, it can produce industrial pigments and act as a metal surface treatment agent to enhance the corrosion resistance and surface smoothness of metal components.

- Agricultural Field: As an important component of micronutrient fertilizers, it supplements molybdenum for molybdenum-deficient crops (such as soybeans and rapeseed). It promotes root development and nitrogen absorption of crops, improving the yield and quality of agricultural products, and is especially suitable for use in acidic soil areas.

- Protection Field: With good corrosion inhibition performance, it can be used for anti-corrosion treatment of metal pipelines and equipment, reducing oxidative corrosion of metal components in industrial environments and extending the service life of equipment.

1. Hazardous Goods Classification and Code: This product belongs to corrosive liquids (inorganic acidic, not otherwise specified), with a dangerous goods transportation code of UN 3264, transportation class 8, and packing group III. It is a non-environmentally hazardous goods and must be handled in accordance with the transportation specifications for corrosive chemicals.

2. Transportation Protection Requirements: During transportation, airtight and leak-proof containers must be used, and mixed loading with strong oxidizers should be avoided. The carriage should be kept cool and ventilated, away from open flames and high-temperature sources, to prevent product decomposition caused by direct sunlight.

3. Personnel and Emergency Protection: Transportation personnel must wear impermeable gloves and safety goggles with side shields. In case of leakage, inert adsorbent materials should be used for absorption, and the waste should be treated as hazardous waste. Discharging into sewers or natural environments is strictly prohibited. If it comes into contact with skin or eyes, rinse immediately with plenty of water and seek medical attention.

4. Storage Connection Requirements: After arriving at the destination, the product must be immediately transferred to a normal-temperature, airtight, and dry storage environment, keeping a safe distance from light, open flames, and high-temperature areas. The storage area should be equipped with emergency rinsing equipment to ensure safety during subsequent use.

1. Excellent Physicochemical Properties: It has a density of 2.498 g/cm³ (at 25℃). In its molecular structure, the number of hydrogen bond donors and acceptors is 30 each, with a topological polar surface area (TPSA) of 30 and a surface charge of 0. It has stable chemical properties, hardly reacting with non-strong oxidizing substances, and is suitable for various production processes.

2. High Purity Controllability: Through the preparation process of "molybdenum trioxide dissolution - ammonium sulfide impurity removal - ammonia concentration adjustment - cooling crystallization", impurities in raw materials can be effectively removed. The purity of the finished product meets the requirements of high-precision fields such as petroleum catalysis and powder metallurgy. Moreover, it contains no known sensitizing components, reducing safety risks during production.

3. Wide Application Compatibility: It not only has catalytic activity (serving as the core component of petroleum cobalt-molybdenum catalysts) but also provides trace elements required by plants (as a raw material for molybdenum fertilizers). Meanwhile, it has metal corrosion inhibition and surface treatment functions, with cross-field adaptability far exceeding that of ordinary molybdate products.

| Specification Item | Specific Parameters |

| CAS Number | 12027-67-7 |

| English Name | Hexaammonium Molybdate |

| Molecular Formula | H₂₄Mo₃N₆O₁₂ |

| Molecular Weight | 588.044 |

| Exact Mass | 593.861450 |

| Density (25℃) | 2.498 g/cm³ |

| Melting Point | 190℃ (decomposition temperature) |

| Solubility | Highly soluble in water |

| pH Value of 5% Aqueous Solution | 5.0-5.5 |

| GHS Signal Word/Symbol | Warning / GHS07 |

Hexaammonium molybdate is an inorganic compound with both stability and multi-field adaptability. As a key raw material in industrial production and agricultural applications, it appears as a colorless to pale green crystalline solid (some high-purity batches present as white crystals). It maintains stable form under normal temperature and pressure, with no obvious pungent odor.

This product is highly soluble in water, and the pH value of its 5% aqueous solution remains in the weakly acidic range of 5.0-5.5, making it compatible with most industrial reaction systems. It loses one molecule of crystal water when heated to 90℃ and decomposes when the temperature rises to 190℃. Therefore, it should be kept away from long-term exposure to high temperatures, open flames, and strong light. It can maintain good chemical stability under conventional storage conditions.

The application scenarios of hexaammonium molybdate cover two major fields: industry and agriculture, with specific application scenarios as follows:

- Petrochemical Industry: As the core raw material of petroleum cobalt-molybdenum catalysts, it is used in desulfurization, hydrogenation, and other reactions during petroleum refining. It improves the purity and quality of petroleum products and is a key auxiliary material for refining enterprises.

- Materials and Metallurgy Industry: On one hand, it can be used to prepare metallic molybdenum (a common raw material for powder metallurgy enterprises, obtaining high-purity molybdenum powder through high-temperature decomposition and reduction). On the other hand, it can produce industrial pigments and act as a metal surface treatment agent to enhance the corrosion resistance and surface smoothness of metal components.

- Agricultural Field: As an important component of micronutrient fertilizers, it supplements molybdenum for molybdenum-deficient crops (such as soybeans and rapeseed). It promotes root development and nitrogen absorption of crops, improving the yield and quality of agricultural products, and is especially suitable for use in acidic soil areas.

- Protection Field: With good corrosion inhibition performance, it can be used for anti-corrosion treatment of metal pipelines and equipment, reducing oxidative corrosion of metal components in industrial environments and extending the service life of equipment.

1. Hazardous Goods Classification and Code: This product belongs to corrosive liquids (inorganic acidic, not otherwise specified), with a dangerous goods transportation code of UN 3264, transportation class 8, and packing group III. It is a non-environmentally hazardous goods and must be handled in accordance with the transportation specifications for corrosive chemicals.

2. Transportation Protection Requirements: During transportation, airtight and leak-proof containers must be used, and mixed loading with strong oxidizers should be avoided. The carriage should be kept cool and ventilated, away from open flames and high-temperature sources, to prevent product decomposition caused by direct sunlight.

3. Personnel and Emergency Protection: Transportation personnel must wear impermeable gloves and safety goggles with side shields. In case of leakage, inert adsorbent materials should be used for absorption, and the waste should be treated as hazardous waste. Discharging into sewers or natural environments is strictly prohibited. If it comes into contact with skin or eyes, rinse immediately with plenty of water and seek medical attention.

4. Storage Connection Requirements: After arriving at the destination, the product must be immediately transferred to a normal-temperature, airtight, and dry storage environment, keeping a safe distance from light, open flames, and high-temperature areas. The storage area should be equipped with emergency rinsing equipment to ensure safety during subsequent use.