+86-13961672821

+86-510-86268020

trust@hi2000.com

trust@hi2000.com

Room 807,No.169 Changjiang road,Huifu plaza,New centre,Jiangyin,Jiangsu China

| Availability: | |

|---|---|

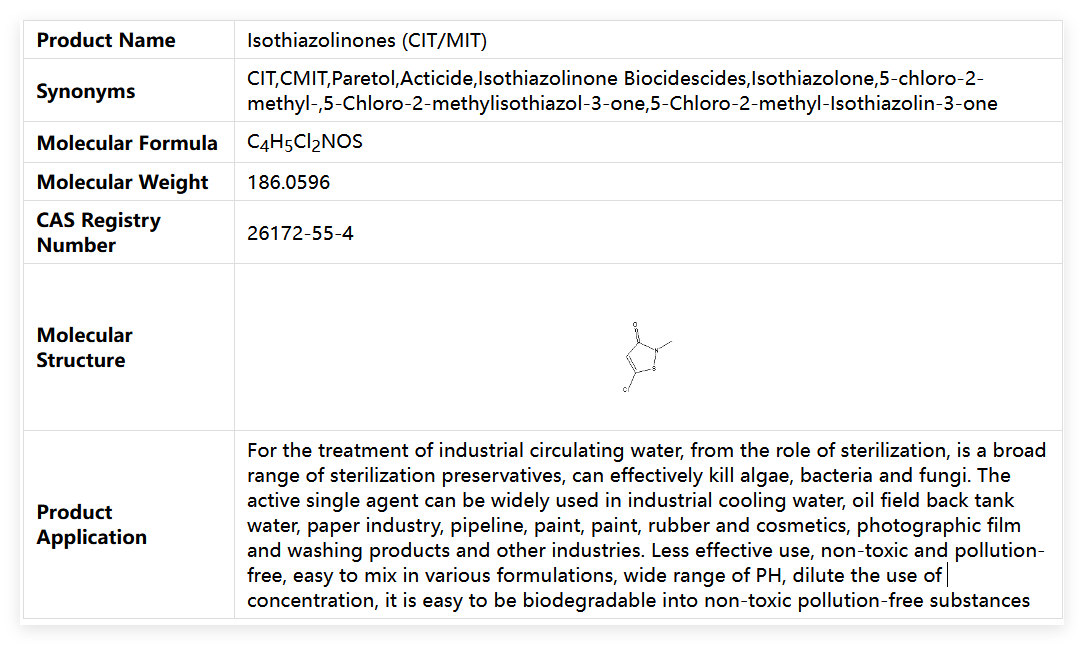

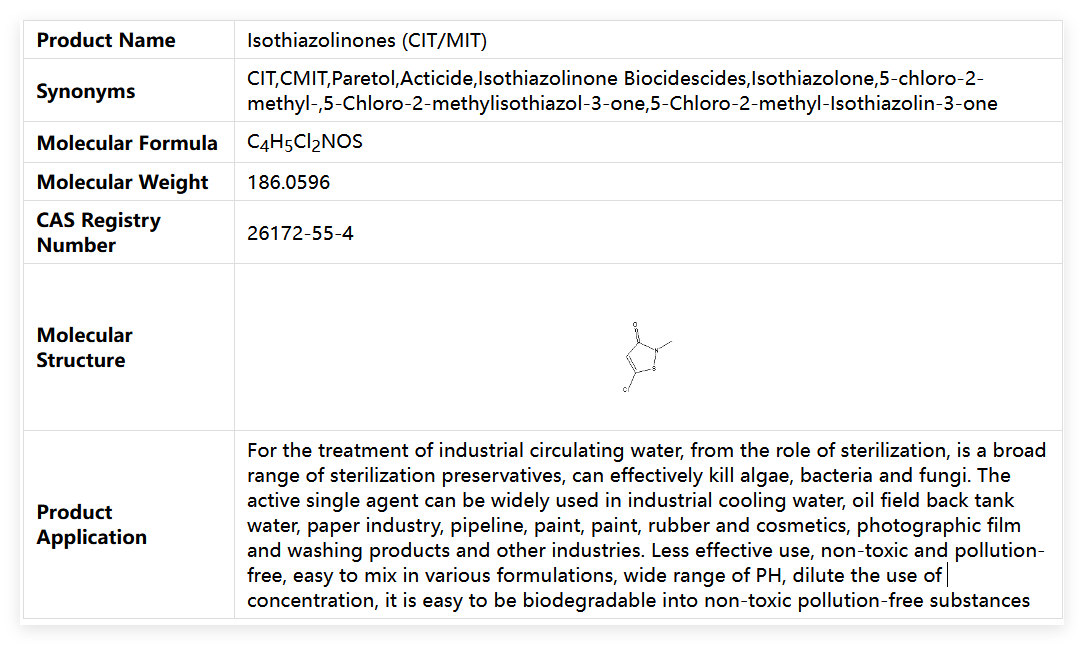

Isothiazolinone is a broad-spectrum bactericidal preservative with 5-Chloro-2-methyl-4-isothiazolin-3-one (abbreviated as CMI) as its core active ingredient. It is usually compounded with 2-Methyl-4-isothiazolin-3-one (abbreviated as MI) at a mass ratio of 3:1 to achieve optimal bactericidal efficacy. Its chemical formula is C₄H₄ClNOS, with a molecular weight of 149.599. Its molecular structure contains a unique isothiazolinone ring, which serves as the core basis for its potent bactericidal effect.

In terms of physical properties, the product appears as a white solid at room temperature and is often present in a transparent to yellow liquid form in industrial applications (to facilitate mixing with various formulations). It has a density of 1.5±0.1 g/cm³, a boiling point of 200.2±50.0℃ (at 760 mmHg), a melting point of 42-45℃, a flash point of 74.9±30.1℃, and a vapor pressure of only 0.3±0.4 mmHg at 25℃. Its low volatility ensures better stability during storage and use. In terms of solubility, it is well miscible with chlorine and most anionic, cationic, and non-ionic surfactants, eliminating concerns about conflicts with common formulation components. For storage, it should be placed in a low-temperature, well-ventilated, and dry warehouse to prevent changes in its chemical properties due to high temperature or moisture.

It irreversibly breaks the protein bonds of microorganisms such as bacteria and algae, rapidly inhibiting microbial growth and causing microbial cell death. It exhibits strong inhibitory and killing effects on common bacteria, fungi, and algae, with no delay in its action process, enabling rapid control of microbial contamination.

It is compatible with commonly used industrial surfactants, oxidants (e.g., chlorine), and quaternary ammonium compounds. Compounding not only does not reduce the efficacy of each component but also enhances the overall bactericidal effect. Meanwhile, it has good chemical stability, can function stably over a wide pH range, and is not prone to decomposition or failure.

After dilution to the application concentration, it can be rapidly degraded into non-toxic and harmless substances by microorganisms in the natural environment, with no residue or environmental accumulation. It meets the requirements of modern industry for "environmentally friendly additives" and avoids secondary pollution to water bodies and soil.

The mass ratio of the core active components (CMI to MI) is strictly controlled at 3:1. This ratio has been verified through experiments to be the range with the highest bactericidal efficacy, ensuring efficient bactericidal effects at low dosages and reducing waste of ineffective components.

It has high bactericidal efficiency, requiring only a dosage of 80-300mg/L in industrial scenarios to achieve the expected effect (80-100mg/L as a bactericide and 150-300mg/L as a slime stripper). Compared with traditional bactericides, it uses less dosage, which can reduce the cost of chemical procurement and dosage for enterprises in long-term use.

It can not only meet the bactericidal needs of large-flow industrial water bodies such as industrial circulating water, oilfield water injection, and papermaking white water but also adapt to the anti-mildew and fresh-keeping of metalworking fluids, coatings, and inks. It can also be used for the preservation of fine chemical products such as cosmetics and photographic films. Its cross-field applicability eliminates the need to purchase different bactericides separately for different scenarios.

The liquid form of the product facilitates metering and dosing, and it can be directly integrated into existing production or water treatment processes without modifying original equipment. No complex pre-treatment is required during use, simplifying operation steps and reducing the operational difficulty for front-line personnel.

Despite its potent bactericidal ability, it has low irritation to the human body and equipment at compliant application concentrations (basic protection is required). It also has no risk of combustion or explosion (with a flash point of 74.9℃, it is not classified as a flammable dangerous good), achieving a balance between "high-efficiency bactericidal effect" and "safe use".

- Circulating Water Systems: As a bactericidal and algaecidal agent, it is dosed once every 3-7 days with a single dosage of 80-100mg/L, which can prevent algae growth and slime adhesion in pipelines, avoiding a decline in heat exchange efficiency or pipeline blockage. If slime has already formed in the system, a dosage of 150-300mg/L can achieve slime stripping. Note: It cannot be used in cooling water systems containing sulfides, and better results can be achieved when compounded with quaternary ammonium salts.

- Oilfield Field: It is used in reinjection water and water injection systems to inhibit the reproduction of microorganisms such as sulfate-reducing bacteria, preventing formation pore blockage or corrosion of oil production equipment caused by microbial metabolites, and ensuring oilfield production efficiency.

- Papermaking Industry: It is added to the white water circulation system to inhibit paper mildew and paper breakage caused by bacterial growth, improving the yield and storage period of finished paper.

- Metalworking/Coatings/Inks: It is added at a concentration of 0.05%-0.4% as an anti-mildew agent into metalworking fluids, coatings, or inks to prevent product deterioration and odor caused by microbial contamination during storage or use.

- Rubber/Latex Industry: It is used in the latex coagulation process and the storage stage of rubber products to prevent latex spoilage or rubber mildew caused by microorganisms, extending the product shelf life.

- Cosmetics/Detergents: As a compliant preservative, it inhibits the growth of bacteria and fungi in products such as emulsions, creams, and shampoos, preventing product deterioration and ensuring user safety (it must comply with cosmetic raw material safety standards).

- Photographic Films: It is added to the film coating or storage environment to prevent microbial erosion of the film substrate, avoiding problems such as blurred images and mildew, and extending the film storage time.

Q1: What is the primary function of Isothiazolinones (CIT/MIT)?

A1: Isothiazolinones (CIT/MIT) is primarily used as a sterilizing and algae-killing agent in industrial circulating water.

Q2: What industries use Isothiazolinones (CIT/MIT)?

A2: It is used in cooling water systems, oil field return tank water, paper industry, pipeline systems, coatings, paints, rubber, cosmetics, and photographic films.

Q3: Is Isothiazolinones (CIT/MIT) biodegradable?

A3: Yes, Isothiazolinones (CIT/MIT) is easy to biodegrade into non-toxic, pollution-free substances.

Q4: How should Isothiazolinones (CIT/MIT) be transported?

A4: During transportation, care should be taken to prevent leakage or moisture exposure.

Q5: Can Isothiazolinones (CIT/MIT) be used in cosmetics?

A5: Yes, Isothiazolinones (CIT/MIT) is commonly used in cosmetics as an antiseptic preservative.

Isothiazolinone is a broad-spectrum bactericidal preservative with 5-Chloro-2-methyl-4-isothiazolin-3-one (abbreviated as CMI) as its core active ingredient. It is usually compounded with 2-Methyl-4-isothiazolin-3-one (abbreviated as MI) at a mass ratio of 3:1 to achieve optimal bactericidal efficacy. Its chemical formula is C₄H₄ClNOS, with a molecular weight of 149.599. Its molecular structure contains a unique isothiazolinone ring, which serves as the core basis for its potent bactericidal effect.

In terms of physical properties, the product appears as a white solid at room temperature and is often present in a transparent to yellow liquid form in industrial applications (to facilitate mixing with various formulations). It has a density of 1.5±0.1 g/cm³, a boiling point of 200.2±50.0℃ (at 760 mmHg), a melting point of 42-45℃, a flash point of 74.9±30.1℃, and a vapor pressure of only 0.3±0.4 mmHg at 25℃. Its low volatility ensures better stability during storage and use. In terms of solubility, it is well miscible with chlorine and most anionic, cationic, and non-ionic surfactants, eliminating concerns about conflicts with common formulation components. For storage, it should be placed in a low-temperature, well-ventilated, and dry warehouse to prevent changes in its chemical properties due to high temperature or moisture.

It irreversibly breaks the protein bonds of microorganisms such as bacteria and algae, rapidly inhibiting microbial growth and causing microbial cell death. It exhibits strong inhibitory and killing effects on common bacteria, fungi, and algae, with no delay in its action process, enabling rapid control of microbial contamination.

It is compatible with commonly used industrial surfactants, oxidants (e.g., chlorine), and quaternary ammonium compounds. Compounding not only does not reduce the efficacy of each component but also enhances the overall bactericidal effect. Meanwhile, it has good chemical stability, can function stably over a wide pH range, and is not prone to decomposition or failure.

After dilution to the application concentration, it can be rapidly degraded into non-toxic and harmless substances by microorganisms in the natural environment, with no residue or environmental accumulation. It meets the requirements of modern industry for "environmentally friendly additives" and avoids secondary pollution to water bodies and soil.

The mass ratio of the core active components (CMI to MI) is strictly controlled at 3:1. This ratio has been verified through experiments to be the range with the highest bactericidal efficacy, ensuring efficient bactericidal effects at low dosages and reducing waste of ineffective components.

It has high bactericidal efficiency, requiring only a dosage of 80-300mg/L in industrial scenarios to achieve the expected effect (80-100mg/L as a bactericide and 150-300mg/L as a slime stripper). Compared with traditional bactericides, it uses less dosage, which can reduce the cost of chemical procurement and dosage for enterprises in long-term use.

It can not only meet the bactericidal needs of large-flow industrial water bodies such as industrial circulating water, oilfield water injection, and papermaking white water but also adapt to the anti-mildew and fresh-keeping of metalworking fluids, coatings, and inks. It can also be used for the preservation of fine chemical products such as cosmetics and photographic films. Its cross-field applicability eliminates the need to purchase different bactericides separately for different scenarios.

The liquid form of the product facilitates metering and dosing, and it can be directly integrated into existing production or water treatment processes without modifying original equipment. No complex pre-treatment is required during use, simplifying operation steps and reducing the operational difficulty for front-line personnel.

Despite its potent bactericidal ability, it has low irritation to the human body and equipment at compliant application concentrations (basic protection is required). It also has no risk of combustion or explosion (with a flash point of 74.9℃, it is not classified as a flammable dangerous good), achieving a balance between "high-efficiency bactericidal effect" and "safe use".

- Circulating Water Systems: As a bactericidal and algaecidal agent, it is dosed once every 3-7 days with a single dosage of 80-100mg/L, which can prevent algae growth and slime adhesion in pipelines, avoiding a decline in heat exchange efficiency or pipeline blockage. If slime has already formed in the system, a dosage of 150-300mg/L can achieve slime stripping. Note: It cannot be used in cooling water systems containing sulfides, and better results can be achieved when compounded with quaternary ammonium salts.

- Oilfield Field: It is used in reinjection water and water injection systems to inhibit the reproduction of microorganisms such as sulfate-reducing bacteria, preventing formation pore blockage or corrosion of oil production equipment caused by microbial metabolites, and ensuring oilfield production efficiency.

- Papermaking Industry: It is added to the white water circulation system to inhibit paper mildew and paper breakage caused by bacterial growth, improving the yield and storage period of finished paper.

- Metalworking/Coatings/Inks: It is added at a concentration of 0.05%-0.4% as an anti-mildew agent into metalworking fluids, coatings, or inks to prevent product deterioration and odor caused by microbial contamination during storage or use.

- Rubber/Latex Industry: It is used in the latex coagulation process and the storage stage of rubber products to prevent latex spoilage or rubber mildew caused by microorganisms, extending the product shelf life.

- Cosmetics/Detergents: As a compliant preservative, it inhibits the growth of bacteria and fungi in products such as emulsions, creams, and shampoos, preventing product deterioration and ensuring user safety (it must comply with cosmetic raw material safety standards).

- Photographic Films: It is added to the film coating or storage environment to prevent microbial erosion of the film substrate, avoiding problems such as blurred images and mildew, and extending the film storage time.

Q1: What is the primary function of Isothiazolinones (CIT/MIT)?

A1: Isothiazolinones (CIT/MIT) is primarily used as a sterilizing and algae-killing agent in industrial circulating water.

Q2: What industries use Isothiazolinones (CIT/MIT)?

A2: It is used in cooling water systems, oil field return tank water, paper industry, pipeline systems, coatings, paints, rubber, cosmetics, and photographic films.

Q3: Is Isothiazolinones (CIT/MIT) biodegradable?

A3: Yes, Isothiazolinones (CIT/MIT) is easy to biodegrade into non-toxic, pollution-free substances.

Q4: How should Isothiazolinones (CIT/MIT) be transported?

A4: During transportation, care should be taken to prevent leakage or moisture exposure.

Q5: Can Isothiazolinones (CIT/MIT) be used in cosmetics?

A5: Yes, Isothiazolinones (CIT/MIT) is commonly used in cosmetics as an antiseptic preservative.