+86-13961672821

+86-510-86268020

trust@hi2000.com

trust@hi2000.com

Room 807,No.169 Changjiang road,Huifu plaza,New centre,Jiangyin,Jiangsu China

| Availability: | |

|---|---|

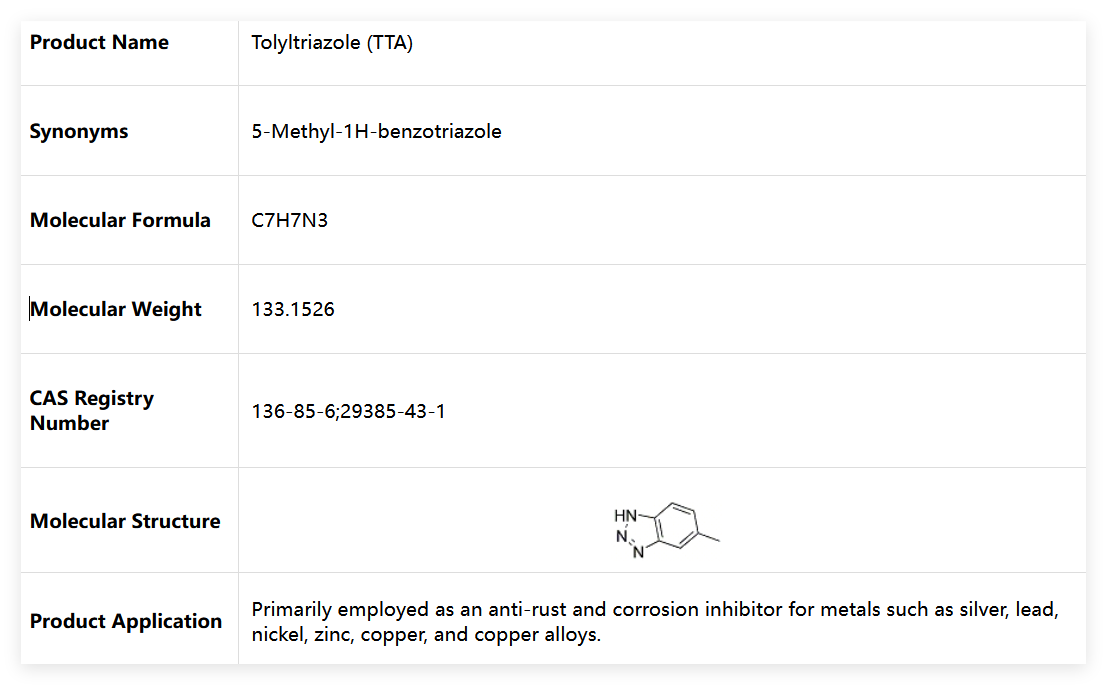

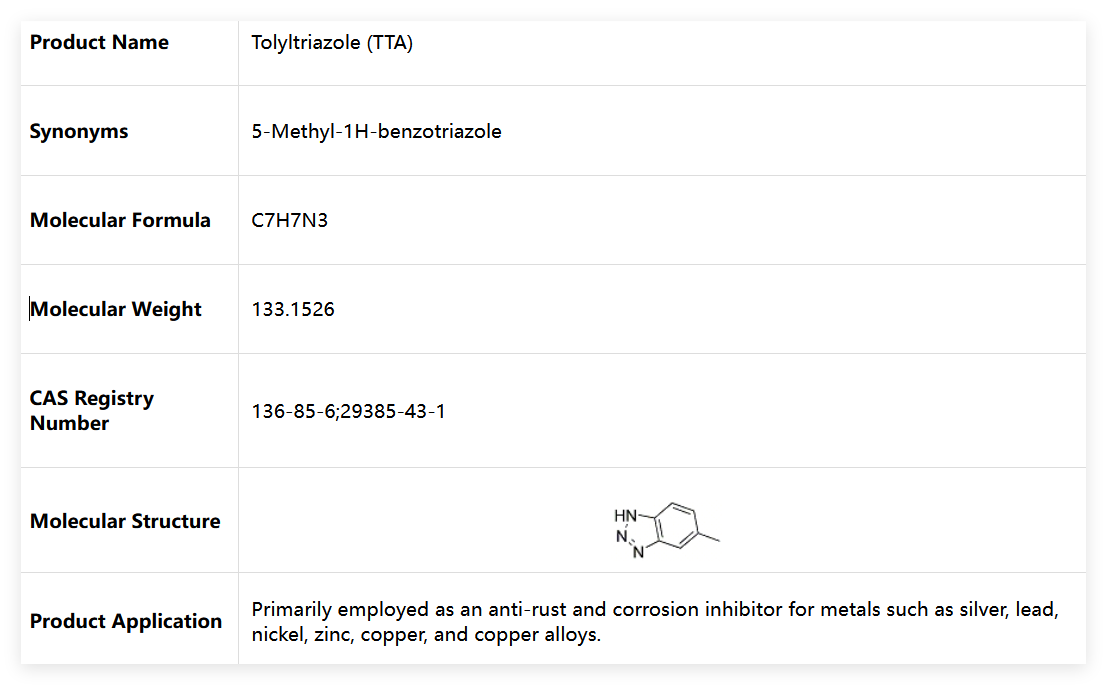

Known chemically as 5-Methylbenzotriazole (CAS: 136-85-6, EC: 205-265-8) and globally marketed as "TTA", this specialized corrosion inhibitor delivers precision metal protection. Recognizable as a white to pale yellow powder (occasionally light brown depending on purity), its weak acidity (pH: 5.5-6.5) ensures compatibility across industrial formulations. Manufacturers familiar with benzotriazole (BTA) recognize TTA as the advanced-generation alternative—engineered for harsh environments where traditional solutions fail.

Visual QC Indicator: Batch-to-batch color consistency confirms manufacturing precision

Solubility Intelligence: Quick dissolution in methanol/acetone versus limited water solubility (6.0 g/L at 25°C) enables flexible system design

Processing often demands resilience against thermal stress. TTA's verified melting point of 80-82°C keeps it stable through plastic compounding, while its virtually nonexistent vapor pressure (0.0±0.8 mmHg at 25°C) eliminates costly material loss during high-temperature cycles.

No vapor loss during tank heating cycles

Maintains integrity during molding/extrusion processes

TTA's hydrogen bonding capacity creates responsive metal adhesion, adapting seamlessly across pH extremes – a strategic advantage in facilities handling both acidic electroplating baths and alkaline cooling systems.

Forms protective complexes with copper ions regardless of solution acidity

Compatible with petroleum-based carriers despite low solubility

The invisible barrier TTA creates (merely 5×10⁻⁷ cm thick) defends against corrosion without interfering with component tolerances or conductivity.

Outperforming standard BTA in pH<5.5 environments, TTA bonds aggressively with copper ions in acidic cleaning processes – the leading cause of premature failure in electronics etching operations.

Operational savings begin at formulation: While purchasing TTA alone ensures protection, blending with 4-methylbenzotriazole (CAS: 29878-31-7) enhances corrosion resistance without reformulation costs. This flexibility delivers tangible outcomes:

23% reduction in etching-related defects

$1.7/ton savings in copper replacement costs

At automotive radiator plants, unprotected copper corrodes in 3-6 months. TTA formulations extend component life cycles by 300%, preventing $23k/minute production halts.

Acidic circuit board etchants dissolve copper traces rapidly. TTA-containing solutions maintain electrical pathways – protecting micro-components during manufacturing.

Moisture and refrigerant interactions corrode condenser coils. Adding 0.5% TTA to coolant systems reduces leak incidents by 40% based on refrigeration OEM field tests.

Copper radiator tubes face acidic coolants at 90°C+. Facilities like Jiangsu Auto Parts Co. reported 900-hour endurance gains using TTA-enhanced protection fluids.

Select grades align with operational scale:

Lab/Validation: Gubiao Grade (98%+, 100mg)

Mid-Scale Processing: Dibo Grade (98%, 5kg drums)

Full Production: Yuanye Grade (98%, custom bulk quantities)

Proper handling eliminates regulatory risk: Store in sealed containers in low-humidity environments (<40% RH). Crucially, segregate from strong oxidizers – our SDS documentation includes detailed isolation protocols meeting EU/US standards.

How does this translate for operators? Simple: Reduced odor exposure headaches and eliminated unexpected HMIS violations. When evaluating corrosion solutions, check suppliers' ISO 9001 certifications – third-party validation guarantees consistency crucial for mission-critical applications.

Known chemically as 5-Methylbenzotriazole (CAS: 136-85-6, EC: 205-265-8) and globally marketed as "TTA", this specialized corrosion inhibitor delivers precision metal protection. Recognizable as a white to pale yellow powder (occasionally light brown depending on purity), its weak acidity (pH: 5.5-6.5) ensures compatibility across industrial formulations. Manufacturers familiar with benzotriazole (BTA) recognize TTA as the advanced-generation alternative—engineered for harsh environments where traditional solutions fail.

Visual QC Indicator: Batch-to-batch color consistency confirms manufacturing precision

Solubility Intelligence: Quick dissolution in methanol/acetone versus limited water solubility (6.0 g/L at 25°C) enables flexible system design

Processing often demands resilience against thermal stress. TTA's verified melting point of 80-82°C keeps it stable through plastic compounding, while its virtually nonexistent vapor pressure (0.0±0.8 mmHg at 25°C) eliminates costly material loss during high-temperature cycles.

No vapor loss during tank heating cycles

Maintains integrity during molding/extrusion processes

TTA's hydrogen bonding capacity creates responsive metal adhesion, adapting seamlessly across pH extremes – a strategic advantage in facilities handling both acidic electroplating baths and alkaline cooling systems.

Forms protective complexes with copper ions regardless of solution acidity

Compatible with petroleum-based carriers despite low solubility

The invisible barrier TTA creates (merely 5×10⁻⁷ cm thick) defends against corrosion without interfering with component tolerances or conductivity.

Outperforming standard BTA in pH<5.5 environments, TTA bonds aggressively with copper ions in acidic cleaning processes – the leading cause of premature failure in electronics etching operations.

Operational savings begin at formulation: While purchasing TTA alone ensures protection, blending with 4-methylbenzotriazole (CAS: 29878-31-7) enhances corrosion resistance without reformulation costs. This flexibility delivers tangible outcomes:

23% reduction in etching-related defects

$1.7/ton savings in copper replacement costs

At automotive radiator plants, unprotected copper corrodes in 3-6 months. TTA formulations extend component life cycles by 300%, preventing $23k/minute production halts.

Acidic circuit board etchants dissolve copper traces rapidly. TTA-containing solutions maintain electrical pathways – protecting micro-components during manufacturing.

Moisture and refrigerant interactions corrode condenser coils. Adding 0.5% TTA to coolant systems reduces leak incidents by 40% based on refrigeration OEM field tests.

Copper radiator tubes face acidic coolants at 90°C+. Facilities like Jiangsu Auto Parts Co. reported 900-hour endurance gains using TTA-enhanced protection fluids.

Select grades align with operational scale:

Lab/Validation: Gubiao Grade (98%+, 100mg)

Mid-Scale Processing: Dibo Grade (98%, 5kg drums)

Full Production: Yuanye Grade (98%, custom bulk quantities)

Proper handling eliminates regulatory risk: Store in sealed containers in low-humidity environments (<40% RH). Crucially, segregate from strong oxidizers – our SDS documentation includes detailed isolation protocols meeting EU/US standards.

How does this translate for operators? Simple: Reduced odor exposure headaches and eliminated unexpected HMIS violations. When evaluating corrosion solutions, check suppliers' ISO 9001 certifications – third-party validation guarantees consistency crucial for mission-critical applications.